dfam

4차 산업혁명의 미래를 주도하는 미래인입니다.

ABOUT

DfAM(Design for Additive Manufacturing) is called DfAM

because the concept of lamination is added

to DFM(Design for Manufacturing) As a design concept to maximize the advantage of 3D printing,

it can be seen as a design for additive manufacturing.

because the concept of lamination is added

to DFM(Design for Manufacturing) As a design concept to maximize the advantage of 3D printing,

it can be seen as a design for additive manufacturing.

NESESSITY

The conventional cutting process of cutting iron had limitations in shape

and manufacturing complex blueprints were impossible. Since additive manufacturing makes a shape by stacking materials, there is no need

to worry about parts impossible to process as there are no limitations to shape. The main purpose for 3D printing is optimized for production of prototypes

and manufacture of customized multi-variety products. 3D printing is a technology necessary for manufacturing products

that cannot be produced by conventional production methods and for special fields

such as high addedvalue industries such as medical, aviation, automobile, mold,

and material fields, and DfAM technology will be used.

and manufacturing complex blueprints were impossible. Since additive manufacturing makes a shape by stacking materials, there is no need

to worry about parts impossible to process as there are no limitations to shape. The main purpose for 3D printing is optimized for production of prototypes

and manufacture of customized multi-variety products. 3D printing is a technology necessary for manufacturing products

that cannot be produced by conventional production methods and for special fields

such as high addedvalue industries such as medical, aviation, automobile, mold,

and material fields, and DfAM technology will be used.

APPLIED

TECHNOLOGY

AND FIELD

TECHNOLOGY

AND FIELD

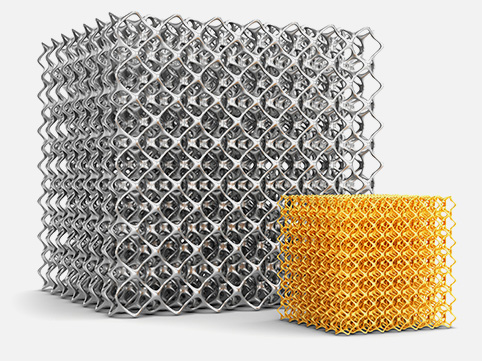

The material most appropriate for DfAM technology

that maximizes the advantages of 3D printing

is metal related materials. This is because complex shapes can be produced,

and in the case of metal with a higher specific gravity

than other materials, unnecessary parts

can be removed or replaced with a grid

to reduce weight. DfAM technology is actively used in metal 3D printing

due to the high efficiency in weight reduction

of metals.

that maximizes the advantages of 3D printing

is metal related materials. This is because complex shapes can be produced,

and in the case of metal with a higher specific gravity

than other materials, unnecessary parts

can be removed or replaced with a grid

to reduce weight. DfAM technology is actively used in metal 3D printing

due to the high efficiency in weight reduction

of metals.

DfAM applied technologies are representative

of grid structures and topology optimization,

and other technologies include production unification,

which makes several parts into one,

and porous structure design, which is specialized

for medical use, and depending on the purpose

and use, all of the above technologies

can be used in combination. DfAM technology has the advantage of reducing

weight and unifying parts while satisfying

the product performance goals (strength, size,

performance) through structural analysis.

of grid structures and topology optimization,

and other technologies include production unification,

which makes several parts into one,

and porous structure design, which is specialized

for medical use, and depending on the purpose

and use, all of the above technologies

can be used in combination. DfAM technology has the advantage of reducing

weight and unifying parts while satisfying

the product performance goals (strength, size,

performance) through structural analysis.

TOPOLOGY

OPTIMAIZATION

OPTIMAIZATION

As a concept of optimizing the structure of an object, it is a concept

that optimizes material distribution within a given design space

while satisfying the performance goals of the product. It is a technology that can save material, unify parts,

and reduce weight at the same time. Since the main purpose is to reduce weight,

it can be optimized according to the purpose and use.

that optimizes material distribution within a given design space

while satisfying the performance goals of the product. It is a technology that can save material, unify parts,

and reduce weight at the same time. Since the main purpose is to reduce weight,

it can be optimized according to the purpose and use.

LATTICE

STRUCTURE

STRUCTURE

It is a technology that can replace weight reducible parts with a grid structure

within the range that does not change the shape of the structure

and make saving material and weight reduction capable at the same time,

and depending on the shape and size of the grid structure, it can be applied

in various fields such as industrial and medical use. Unlike topology optimization, it is effective when the structure needs to be upheld,

and the grid structure can substitute the most important support role

in metal 3D printing.

within the range that does not change the shape of the structure

and make saving material and weight reduction capable at the same time,

and depending on the shape and size of the grid structure, it can be applied

in various fields such as industrial and medical use. Unlike topology optimization, it is effective when the structure needs to be upheld,

and the grid structure can substitute the most important support role

in metal 3D printing.